It took a weekend away full of wining and dining up in the city lights, but with timing Don Bradman would have been proud to own, I broke the news to the Minister for Excessive Windsurfing Expenditure. "Woger was wight. I really need to make a FF22."

When I peeked above the tablecloth again, instead of seeing the expected smoldering ruins of once pristine linen, my beloved seemed calm and not unhappy about the idea. I think it was my first 'barber' haircut in five years that swayed the deal. Perhaps the glass or two of bubbles didn't hurt either.

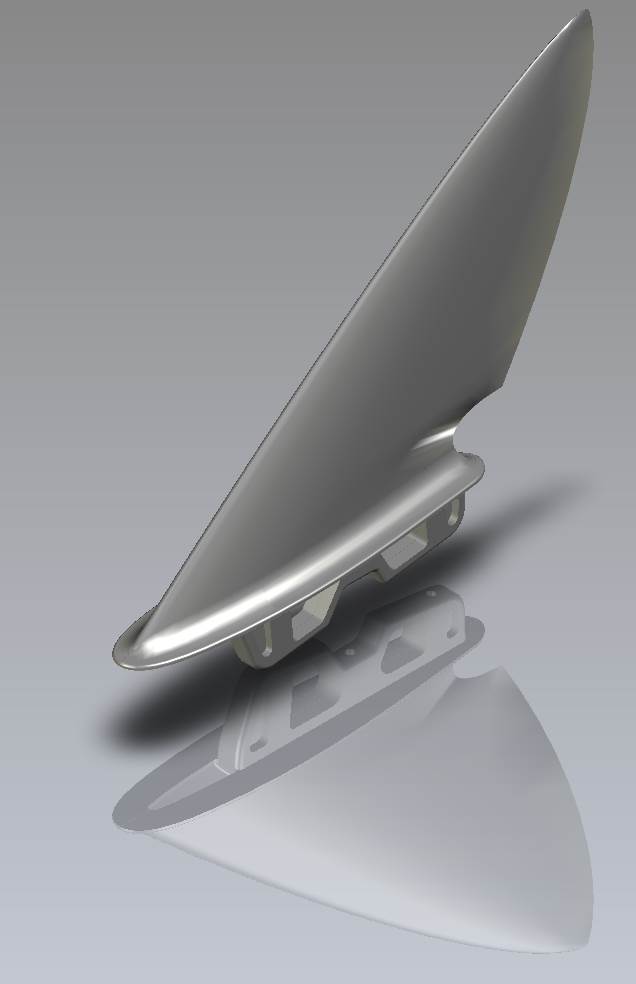

In any case, I got cracking on the process of developing the FF22. As usual I had dramas. This time it was the CAD side of things. I employed two different professionals to put the design into digits and both of them proceeded to disappear off the face of the planet. Then, in steps SB member Swoosh. Bam! And the job is done. Now the results are in and its time to get this show on the road. There are no really big changes to the format, just some minor tweaking.

The main difference is the box has been cleaned up in its structural design. The outline is Powerbox but has no taper. This has been done to reduce the amount of grinding needed to make a Powerbox from the raw casting. The fin will still function happily in a Tuttle box because the fit and loading all occurs at the fillet level, not the box itself. The box section has been moved 10mm forward to ensure adequate support for load distribution at the rear of the fin.

Swoosh is now having a crack at setting up the fin and core box patterns to enable the moulds to be CNC milled directly. In an ideal world, these resultant pattern moulds will go straight to the foundry to be cast. Stay tuned :-)

Swoosh is now having a crack at setting up the fin and core box patterns to enable the moulds to be CNC milled directly. In an ideal world, these resultant pattern moulds will go straight to the foundry to be cast. Stay tuned :-)

This is the best way to do things imo, I'm glad that you're able to get access to a CNC machine in order to do things properly.

It's great to see this fin progress from ideas to reality.

Excellent work!

A comparison of the three fins. Ignore the hollow sections ( and weights) of the 20 and 24, the foundry patterns look more like that of the 22. Swoosh has done a really nice job of ensuring the 22 lies midway betwwen the 24 and 20. Note the tidied up box section of the 22.

And Swoosh's first draft of the patterns for CNCing.

Nice read and great work Woss I'll have one please .

..... As soon as those wotten romans 'Welease Woger' ![]()

( not brave enough to replace the 'r ' in romans with a 'w')

Thanks Slugger, keep the orders coming people and I get my 10% royalties on the 22. Somehow this equates to me owing Ross money![]() .

.

With further diplomacy due my incessant efforts with the Minister of Safari's trip to S Afr, Zimbabwe and Botswana, I can now advise all systems go and have the patterns ready to be poured. I am booked in two weeks for some prelim pours.

And the freak chance meet at the Uni Awards night, lead to a collab with a fellow student to do an initial FF18 sketch. Don't get excited, this has a bit of work to do to it yet and only has the surface area of two fingernails at well under 190cms. (half the size of a Delta 21.)

If I ever get to point of casting, they will be rare a hens teeth - I will be will be using a 3D print to create the sand moulds and there will be no hollow - there is no room.

With further diplomacy due my incessant efforts with the Minister of Safari's trip to S Afr, Zimbabwe and Botswana, I can now advise all systems go and have the patterns ready to be poured. I am booked in two weeks for some prelim pours.

Yay! keen to try the cut down 22FF - 16cm for Budgy! ![]()

![]()

![]()

I have Swindy's version in the car, but that's still hollow, so is possibly a little thicker. I could have tried it yesterday if I'd got out a bit sooner, before the wind died.

After a brief chat to Nebbian, it was decided that if you can be Batman, you should always be Batman.The 3D print of the FF18 rising from the printer floor.![]()

Print finished

Nebs shows why he is a gun in the vineyard with the secateurs and trims excess.

and ta dah! . Fully Batman bro.![]()

Must... resist... urge... to... put... it... in... my... board... ![]()

I wonder if you made it 1mm thinner all over, then laid up carbon to get it back to thickness, how long it would hold your weight?

I wonder if you made it 1mm thinner all over, then laid up carbon to get it back to thickness, how long it would hold your weight?

I've actually discussed this with Fangman before ![]()

My gut feeling is that it would work, this plastic is quite strong and stiff in compression (ie harder than wood), and you can adjust the infill to get it stronger as well. The harder part would be to get a good bond between the plastic and the carbon. You probably don't want it delaminating at speed.

I wonder if you made it 1mm thinner all over, then laid up carbon to get it back to thickness, how long it would hold your weight?

I've actually discussed this with Fangman before ![]()

My gut feeling is that it would work, this plastic is quite strong and stiff in compression (ie harder than wood), and you can adjust the infill to get it stronger as well. The harder part would be to get a good bond between the plastic and the carbon. You probably don't want it delaminating at speed.

Wow that's a good memory Nebs, but as far as I recall my contribution was less practical...something along the lines of filling the inside of the fin with carbon tubes and bonding it altogether with two pack foam??

It remains an ambition of mine to see the day when we design one day, prototype print the next, and hit the water to test in the arvo ![]()

Stretchy I think that probably Swindy is the 'go-to' guy on this one, as he has more boards, more sails and I think even more fins that I have ![]()

As a really rough guide and guesstimate:

28 cm - sails > 8.0m

24 cm - sails = 6.5 -> 8.0m

22 cm - sails = 5.5 -> 7.0m

20 cm - sails = 5.0 -> 6.5m

18cm - sails < teatowel

Take that info with a pinch of salt, cos it's based primarily on my weight and the PartyBarge set up. As I said, whatever Swindy says is probably a better real-life scenario.

The cut-off versions seem to be working quite well and appear to retain a good chunk of their lifting power despite the loss of length. Swindy has done some work with thinning the foil thickness in his woody versions. From what I understand, there are no surprises, and the thinned foil is quicker at the expense of lifting power/pointing ability.

![]() thanks

thanks

I find board width has more to do with the fin I select.

80-85=28

70-75=24 or 26 with big sail if you have one like I do.

60-65=22

55-60=20 or speed version of the 22 if you have one.

45-55=18 or in my case the 17 that I made.

This is only based on my experience at my weight of 95kg. Lighter people will get away with smaller. ![]()

Swindy, im 105kg ,boards 130-150 litre 70-75wide. Sails 7.5-9.5. What size fins should i be looking at?

Swindy, im 105kg ,boards 130-150 litre 70-75wide. Sails 7.5-9.5. What size fins should i be looking at?

up to 18 knots a 28 and above that a 24 I would think. You don't want to overpower a FF too much as they may want to chuck you off due to the massive lift they create. Fangman is a bit heavier than you and has found this out on several occasions leaving some massive dents in the estuary.![]() Much to our enjoyment.

Much to our enjoyment.![]()

Swindy, im 105kg ,boards 130-150 litre 70-75wide. Sails 7.5-9.5. What size fins should i be looking at?

up to 18 knots a 28 and above that a 24 I would think. You don't want to overpower a FF too much as they may want to chuck you off due to the massive lift they create. Fangman is a bit heavier than you and has found this out on several occasions leaving some massive dents in the estuary.![]() Much to our enjoyment.

Much to our enjoyment.![]()

olskool, what Swindy fails to mention is that most of the time, in the few seconds before aforementioned dent making, I have nailed a speed run and just pulled off a double inverted heli-vulcan with a triple backward loop, no handed duck-gybe. Yep, I really am just a better version of him.![]()

In between times, I have found that the FF28 maxes out in the low thirties speed wise - that is, the vertical lift at this speed really does become a handful and is enough to lift 120kgs, board and all, clear of the water. So if you think you will stay sub 30, the FF28 will be the pick. If you are going 30+ regularly, the FF24 would be better. ![]()

Does anybody else remember swindy saying he didn't know much about foils??

But he was just grinding them by eye to what he thought looked right.

Well I've just put the profile gauge on the swoody 18 and compared to my favourite foil, the Yoyo modified 9% eppler.

Took 3 samples from the base to the tip.

Here's the base

Here's the mid point.

and here's the tip.

I thought I was good at foiling by eye, and I've had years of practice. This is excellent work swindy! I'm very impressed.

May get a chance to try it on Tuesday, we'll see what happens.