Makntracks, not sure about rails yet - haven't thought that far ahead. Had one quick read thru Geoff's instructions and decided I need a beer.

Now we are alone...... I feel pretty damn sad when I go down into my garage now - it's a weird feeling especially since I was only talking to him last week.

As for UV stability - no idea sorry. Is it a worry? I have a feeling there might be additives I can put in it if I glass over the external?

1Bonehead I'm just using the WS epoxy with a slow hardener and 403 filler as glue - it's amazing how strong it sticks the wood (the wood will snap before any joins do - a bit like good welding?)

Thanks for the advice guys its really appreciated. Just waiting for the Paulowina to turn up from Vic. Plans are printed and look huge when you roll them out. Going to do a solid Paulowina stringer with 2.5mm Model Aircraft Ply for the spars. The ME Ply is marine rated, light, flexible and strong. Next thing will be to borrow a mates thicknesser and table saw and mow all the old WRC cladding boards I have found down to 6mm x 45mm (Nails and staples have been carefully removed!). Sunny days have been a bit few and far between down here and make all the mess outside! The board I am making has a Vee in the last 2/3rds of the board so I am trying to work out how I can vee the gluing side accurately and still leave enough in the strip to sand the bottom shape, not sure I want to split the centre strip and bevel the edges.....should be interesting.

WRC is all thicknessed down, cutting it into strips next

Hey sorry I haven't replied / up to my ears with work. I've got a few specs for finishes are pretty fail safe. PM me with specific queries and I'll fire back solutions.

Cheers,

Adam

Just trying to get the templates onto the wood and cut, got some contact-spray adhesvie, looks like its off to borrow a mates bandsaw. Jigsaw is too rough and I need to go n buy a beltsander anyway, long weekend coming so hopefully some progress............![]()

Yeah would be alot of work making up all those templates.. makes the $150 for them look cheap..

Im still doing the rails on mine, taking for ever. doing a hollow strip rail so taking forever.

Would love to hear some info on the finishes manoverboard. Ill send you a pm once i get ready to purchase.

Yeah would be alot of work making up all those templates.. makes the $150 for them look cheap..

Im still doing the rails on mine, taking for ever. doing a hollow strip rail so taking forever.

Would love to hear some info on the finishes manoverboard. Ill send you a pm once i get ready to purchase.

ohhh the rails yeah they look interesting...post how you go! Best advice I have seen was to draw the high point of your rail along the side of your board and then sand/plane to that. Sharp down the tail and work it into 60/40 then 50/50 as you move to the nose. Good luck mate!

One of the really nice finishing touches I do for my customers are custom leash loops. Generally I create something with whatever material I have to hand and to compliment the board. Not always easy but heaps of fun and the results speak for themselves!

Mate they look amazing!!!!!! Hope mine turns out even half as good!!!!!! I have an even greater respect for the guys who shape boards now! Gone back to cutting templates with a jigsaw and then will have to sand them back, long process. Never let a lack of skill or ability stand in the way! Just gotta be patient.

Mate they look amazing!!!!!! Hope mine turns out even half as good!!!!!! I have an even greater respect for the guys who shape boards now! Gone back to cutting templates with a jigsaw and then will have to sand them back, long process. Never let a lack of skill or ability stand in the way! Just gotta be patient.

Hey mate those boards have been built and shaped by guys who have never shaped before. I just finish them off. Obviously I have a few tricks to getting the best definition and shape from sometimes less than ideal rails and fairing - I refuse to reshape any of the wood beyond a light touchup.

Have fun you'll do just fine mate!

Mate they look amazing!!!!!! Hope mine turns out even half as good!!!!!! I have an even greater respect for the guys who shape boards now! Gone back to cutting templates with a jigsaw and then will have to sand them back, long process. Never let a lack of skill or ability stand in the way! Just gotta be patient.

Hey mate those boards have been built and shaped by guys who have never shaped before. I just finish them off. Obviously I have a few tricks to getting the best definition and shape from sometimes less than ideal rails and fairing - I refuse to reshape any of the wood beyond a light touchup.

Have fun you'll do just fine mate!

Thanks guys a bit of encouragement goes aloooonnng way!

Totally agree with Makintracks if you can get the frames laser cut or done on a CNC its worth doing, Pawlonia stringers are a bitch to cut out!

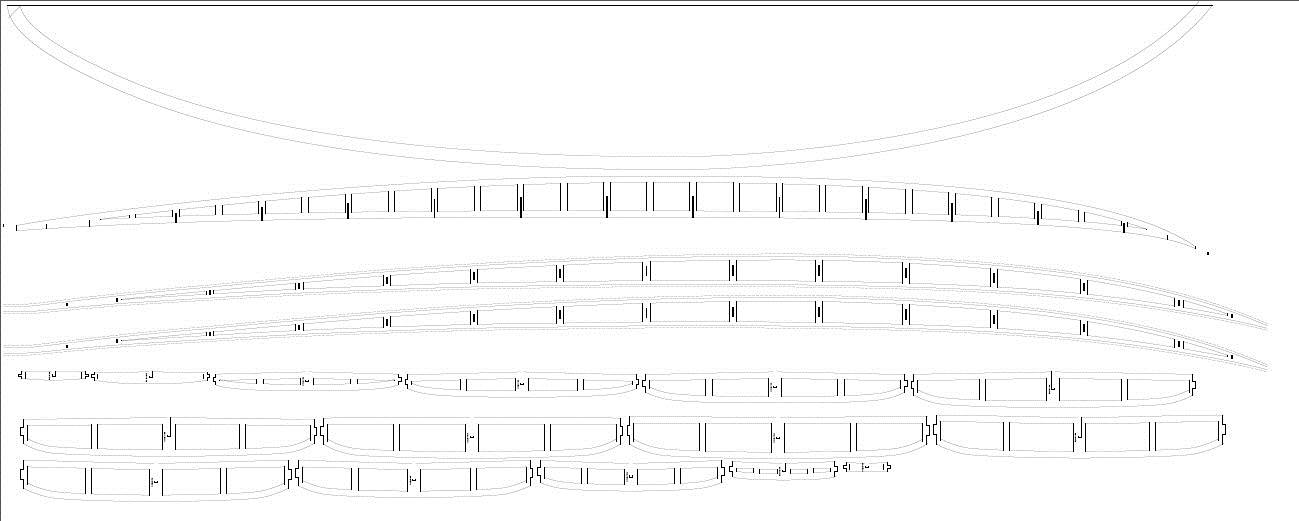

Agreed. Setting out and cutting 22 ribs, the spine and 2 perimeters was a nightmare.

Slowly getting there now though.

Getting rails looking right is a lot of fun - not.

Agreed. Setting out and cutting 22 ribs, the spine and 2 perimeters was a nightmare.

Slowly getting there now though.

Getting rails looking right is a lot of fun - not.

Mate that looks NICE!!!!!!!! You are well on the way. Good looking shape hows the weight of the board going? Rail shaping is still a future nightmare for me

Thanks guys.

It's funny, I've really enjoyed the challenge so far (although it was a damn awful about Geoff)

I've suddenly gotten a bit tired of it for some reason, so I sanded it all smooth and painted a coat of resin over the lot. (looks nice up on the rack for now)

My garage looks like a war zone, so I needed to stop and clean up.

No idea if it's sensible or what, but I think I'll leave it for a while now and look into how to glass it properly, make fin/s for it etc in a few months time.

I would really appreciate any advice on the "UV" issue (I am a complete novice still ... but hopefully learning)

In meantime, I have a "cut in half" sup I'm keen to have a go at putting back together.

(it was an awesome board that I really loved surfing and windsurfing)

While working on my wood project I've worked out that epoxy resin seems to glue EPS foam together really well.

So I'm thinking, how about glueing it back together, then wrapping some carbon fibre around it, then normal glass on top - would that work?

All thoughts welcome......

ET

Thanks guys.

It's funny, I've really enjoyed the challenge so far (although it was a damn awful about Geoff)

I've suddenly gotten a bit tired of it for some reason, so I sanded it all smooth and painted a coat of resin over the lot. (looks nice up on the rack for now)

My garage looks like a war zone, so I needed to stop and clean up.

No idea if it's sensible or what, but I think I'll leave it for a while now and look into how to glass it properly, make fin/s for it etc in a few months time.

I would really appreciate any advice on the "UV" issue (I am a complete novice still ... but hopefully learning)

In meantime, I have a "cut in half" sup I'm keen to have a go at putting back together.

(it was an awesome board that I really loved surfing and windsurfing)

While working on my wood project I've worked out that epoxy resin seems to glue EPS foam together really well.

So I'm thinking, how about glueing it back together, then wrapping some carbon fibre around it, then normal glass on top - would that work?

All thoughts welcome......

ET

Yes Geoff's loss was very sad. The board looks awesome, I am lucky and have a couple of local shapers who are good mates that are going going to give me a hand with the rail shapes when the time comes. Plenty of time to finish it mate when your energy comes back, its a HUGE project and you're wife will probably be happy to see you again, mine is still looking for me. The guys down here reckon just standard 2oz glass & board resin or epxoy will do. Getting all the spars n stringer straight and level now for gluing.....haven't drunk enough beer to go to the next step yet!

Yeah..…the rails….. in retrospect I would try them differently. With Geoff gone, and nobody to get advice from, I just cut them out roughly, glued them on one at a time until I had 6 on either side, then tried to shape them – using hand planes/grinders/belt sanders, etc. Looks ok, but I’m not 100% happy.

If I ever do it again, I would try to hollow them out a bit. I think that the 12 solid chunks added to either side has added a fair bit of weight to it - (with a coat of resin all over it – it now weighs in at 13.7kg. And I’ve still got to put glass on it yet + fin, vent plug, leash plug).

Not going to bother installing plugs for fin/s at this stage (although I did put in blocks for them) I think I’ll just router out a hole to glue in a paulownia fin I made up myself. I also toyed with the idea of making a handle out of paulownia and drew up a few plans for it, but subsequently gave it a miss this time.

1bonehed, your design seems to have a lot less ribs than mine? Mine has 21 or 22 ribs (can’t remember exactly) – with a concentration around the middle of the board.

For the record, I think the wife would rather see me get back into it again… (she enjoyed having control of the remote for all that time)

Yeah..…the rails….. in retrospect I would try them differently. With Geoff gone, and nobody to get advice from, I just cut them out roughly, glued them on one at a time until I had 6 on either side, then tried to shape them – using hand planes/grinders/belt sanders, etc. Looks ok, but I’m not 100% happy.

If I ever do it again, I would try to hollow them out a bit. I think that the 12 solid chunks added to either side has added a fair bit of weight to it - (with a coat of resin all over it – it now weighs in at 13.7kg. And I’ve still got to put glass on it yet + fin, vent plug, leash plug).

Not going to bother installing plugs for fin/s at this stage (although I did put in blocks for them) I think I’ll just router out a hole to glue in a paulownia fin I made up myself. I also toyed with the idea of making a handle out of paulownia and drew up a few plans for it, but subsequently gave it a miss this time.

1bonehed, your design seems to have a lot less ribs than mine? Mine has 21 or 22 ribs (can’t remember exactly) – with a concentration around the middle of the board.

For the record, I think the wife would rather see me get back into it again… (she enjoyed having control of the remote for all that time)

Hi sorry bout the time between posts but got smashed by work n domestic chores, we can actually see the dog in the backyard now instead just hearing her! I only had a "Slice" every 200mm and then 100mm from each end in the plan from the AKU Shaper so thats where the HW Template maker puts the spars and there are 15 in all. I had a few less spars than you had to deal with which is good cause they all tend to warp with humidity. Bonehead by nature, bonehead by name I even managed to accidentally swap two of the middle spars around into the wrong order, lucky I hadn't glued to much in and got them in the

right order again!At one stage the stringer was straight Sunday arvo then Monday it had a wicked "S" bend in it after a storm in the evening! It has certainly made getting the rail strips on while keeping the spars straight interesting! Think I am now ready to start the deck!

Great thread, though a little scary. My son has just decided to make a hollow wood board for his HSC so the info here is a great help.

Great thread, though a little scary. My son has just decided to make a hollow wood board for his HSC so the info here is a great help.

Great project, he will learn heaps like we all have!!!!!!!!!! Def not scary, just be patient n deal with the probs as they come up

Yeah NNSUP. It's not scary, it's great fun. Just gotta not rush anything. I made that mistake, but thoroughly enjoyed experience so far.

I've stopped for a break away from it, while I fix my broken board, and while I find someone to help me with the final glassing & fitting fins etc.

I'll put up more photos of the process I went through - may help others with ideas?

ET

This is the other project that's taken my attention away from wood board temporarily.

No idea really what I'm doing - but decided to have a go anyway (the peice of carbon fibre is the only real cost - about $60).

Welcome any comments / criticisms.

Going to give it a test run before I spend any more time or money on it (just waiting for a decent breeze to blow up)

Hopefully it doesn't just snap in half and I can use as my windsurfer, and I will finish it off better with paint / padding etc.

Nice job my only comment is about using that foam filler , it won't last and will break down with pressure especially being on the deck and cause a soft spot .You would have been better off to shape a foam block. Maybe put a couple more patches over the top of it. I was hoping you were making a 2 piece board. Now there's a cool project ![]()

Nice job my only comment is about using that foam filler , it won't last and will break down with pressure especially being on the deck and cause a soft spot .You would have been better off to shape a foam block. Maybe put a couple more patches over the top of it. I was hoping you were making a 2 piece board. Now there's a cool project ![]()

Maybe even a couple of dowls or aluminium tubes pushed in for strength, hard to line up tho. Top deck is done on mine and all the blocks are in for the fins etc. Time to start working on the bottom.

Thnx Piros, if it falls apart I'll do that next time.

1Bonehead, I had people suggest dowels, then others said the sheet of carbon fibre wrapped around it would be more than enough.

It's cost me bugger-all anyway, so if it doesnt work, or snaps in two - no real loss.

I've already had a couple of quick windsurfs on it and it was fine.

Just finished painting it & sticking some deck grip on now - so ready to try a sup surf next.

Thnx Piros, if it falls apart I'll do that next time.

1Bonehead, I had people suggest dowels, then others said the sheet of carbon fibre wrapped around it would be more than enough.

It's cost me bugger-all anyway, so if it doesnt work, or snaps in two - no real loss.

I've already had a couple of quick windsurfs on it and it was fine.

Just finished painting it & sticking some deck grip on now - so ready to try a sup surf next.

Nice way to finish it off. Forget about the dowels thats a bit 'old hat'. The only thing I would do differently is to lay the carbon on 45deg to the centre and to taper the patch to a point on the centreline - I go 45deg again. It puts 2 x the fibres across your join and the taper graduates the flex.

Also if you are going to shorten a board take advantage of the extra material and cut the join in a V rather than 90deg butt joint - infinitely stronger and you can they use less additional reinforcement. If its a dirty break use the randomness of the snap as your glue line as best you can.

Nice one!

Holy crap 1bonehead that is sweet!

You've inspired me to get my half done job down off the wall and get into it again.

New year's resolutions - surf even more often, and get wooden board finished pronto!

![]() Agree with you 100% the rails are painful!!!! WRC doesn't like bending but it can be persuaded eventually!

Agree with you 100% the rails are painful!!!! WRC doesn't like bending but it can be persuaded eventually!

![]() Agree with you 100% the rails are painful!!!! WRC doesn't like bending but it can be persuaded eventually!

Agree with you 100% the rails are painful!!!! WRC doesn't like bending but it can be persuaded eventually!

Man yours inspired me to get going!!!!!