hey,

Im in Colorado. I have experience with installing fin boxes and shortening nose n tail, plus rails. I've removed and repositioned mast , and footstrap inserts.

Im ready to start my first board from a blank. I have this already its EPS2lb. I plan to use core cell on the bottom, and a semi sandwich. The deck is the question, I'm using really good source, but being told by others the plan is wrong.

The deck I'm looking to inlay core cell , in the footstrap area . Deck will be glass, glass, carbon over areas deemed necessary, then glass. Option of S glass E glass 6oz, 4 oz EGlass, rails will have carbon , glass. Nose top n bottom Kevlar.

Question being, is the deck plan sound enough without the sandwich of core cell?

i realize this won't last forever, it might not end up worth a toss.

229X 64.5. Tri fin

Weight gain a primary concern, vacuum most of it.

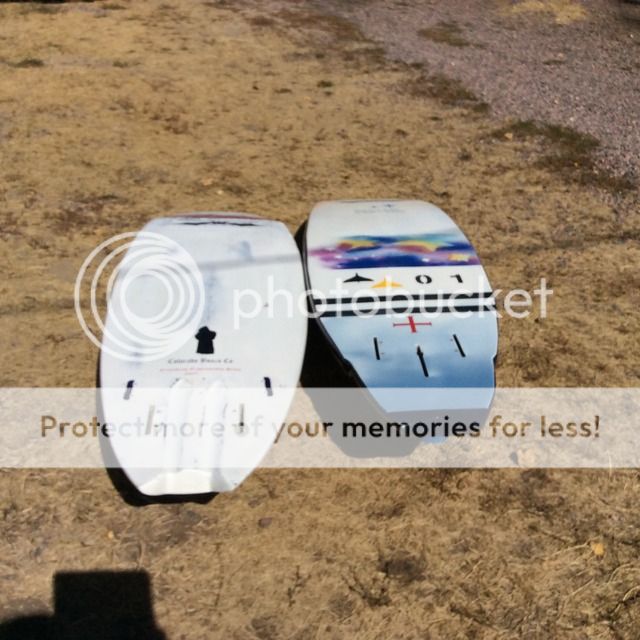

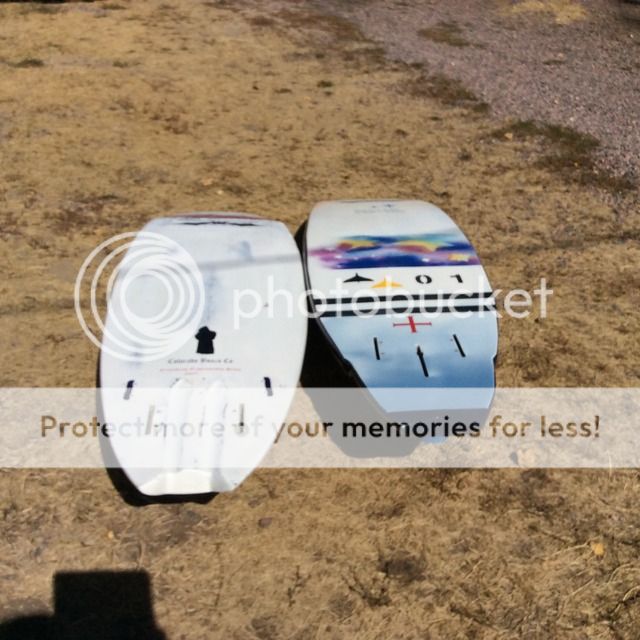

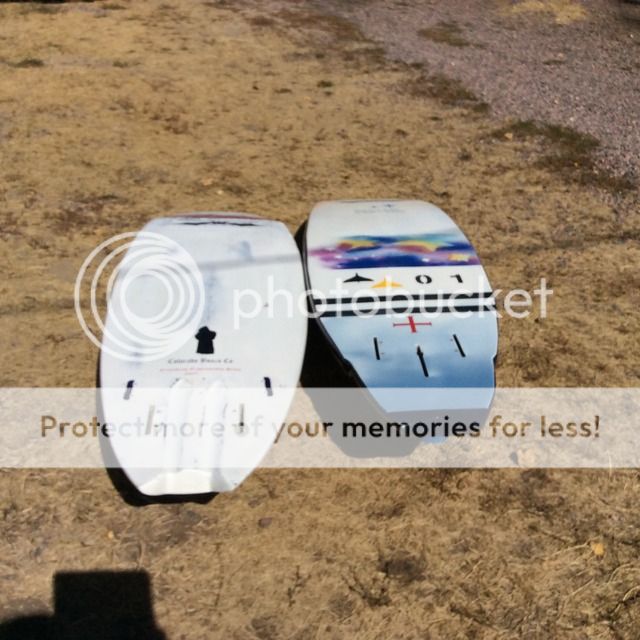

These 2 were my last projects, left was a Naish Titan , 109 l 2000 or so, right a Mistral Naish 1999 104l

These 2 were my last projects, left was a Naish Titan , 109 l 2000 or so, right a Mistral Naish 1999 104l

Awesome reply mate... shame u missed answering his question.

I'd at least use sandwich construction between mast track and rear footstrap, but don't cut it off square. It should be tapered from in front of the mast track back to the front of the front footstrap, other wise you risk breaking the board at the junction.

When gybing and slogging, the front foot is often in front of it's strap, I've seen boards fail because this area wasn't stiff enough.

The thing is, to get any stiffness without a sandwich construction, the lay up is probably going to be just as heavy or perhaps heavier than with.

You'd need to do some real homework on this and make sure you're actually saving a bit of weight.

I wet out 4oz cloth on the table for the underneath layer, place on board then vacuum the corecell to that. Then I use 2 layers of 4oz on top of that at about 10 to 15 degrees off straight, with the two layers in opposing directions. This is also vacuumed on, the bottom gets just enough q-cell bog to sand to a flat finish, the deck gets a very runny q-cell mix squeegeed on to fill and pin holes. I don't worry about a true filler coat here as it's going to have a sugar deck anyway.

The impact area, top and bottom get a triangle of 6oz carbon, between tail and mast track at 45 degrees underneath the corecell. and patches of carbon under each footstrap.

This ends up strong and light, admittedly I don't weigh much, but some of my boards are 10years old and still going strong. My 90liter board is around 13lbs, but that's using 23kg/m3 foam, if you used 13/kg/m3 foam that weight would come down by about 2lb, and perhaps not quite last 10years.

I'm not sure what your 2lb foam is, obviously not a cubic meter, is it a cubic yard? These maths are a bit hard this time of night.

Hmmm now I'm puzzled, just did this.

michael@Mate:~$ units 2lb/yd3 kg/m3

?* 1.1865528

?/ 0.84277747

michael@Mate:~$ units 2lb/ft3 kg/m3

?* 32.036927

?/ 0.03121398

So if it's cubic yards it's way light, I don't believe foam this light is possible.

If it's cubic feet, it's on the (very) heavy side, and you may well get away without much sandwich construction. If you can get 1lb foam and use full sandwich, I think you'd have a better board.

Although it occurs to me, your foam may be the closed cell extruded not expanded open cell variety. If it's the closed cell stuff, I did make a board ages ago, with a sandwich bottom, reinforced footstrap area, and just 2 or three layers of glass over the rest of the deck.

It lasted OK, but the unreinforced deck dented fairly easily. It's so nice not having to worry about dealing with vents and their problems, that the extra weight is probably worth it.

These 2 were my last projects, left was a Naish Titan , 109 l 2000 or so, right a Mistral Naish 1999 104l

Awesome reply mate... shame u missed answering his question.

I could have done the same error ... I posted the photos after th OP, as the posting flormat is different to what I'm used to to.

I'd at least use sandwich construction between mast track and rear footstrap, but don't cut it off square. It should be tapered from in front of the mast track back to the front of the front footstrap, other wise you risk breaking the board at the junction.

When gybing and slogging, the front foot is often in front of it's strap, I've seen boards fail because this area wasn't stiff enough.

The thing is, to get any stiffness without a sandwich construction, the lay up is probably going to be just as heavy or perhaps heavier than with.

You'd need to do some real homework on this and make sure you're actually saving a bit of weight.

I wet out 4oz cloth on the table for the underneath layer, place on board then vacuum the corecell to that. Then I use 2 layers of 4oz on top of that at about 10 to 15 degrees off straight, with the two layers in opposing directions. This is also vacuumed on, the bottom gets just enough q-cell bog to sand to a flat finish, the deck gets a very runny q-cell mix squeegeed on to fill and pin holes. I don't worry about a true filler coat here as it's going to have a sugar deck anyway.

The impact area, top and bottom get a triangle of 6oz carbon, between tail and mast track at 45 degrees underneath the corecell. and patches of carbon under each footstrap.

This ends up strong and light, admittedly I don't weigh much, but some of my boards are 10years old and still going strong. My 90liter board is around 13lbs, but that's using 23kg/m3 foam, if you used 13/kg/m3 foam that weight would come down by about 2lb, and perhaps not quite last 10years.

I'm not sure what your 2lb foam is, obviously not a cubic meter, is it a cubic yard? These maths are a bit hard this time of night.

Hmmm now I'm puzzled, just did this.

michael@Mate:~$ units 2lb/yd3 kg/m3

?* 1.1865528

?/ 0.84277747

michael@Mate:~$ units 2lb/ft3 kg/m3

?* 32.036927

?/ 0.03121398

So if it's cubic yards it's way light, I don't believe foam this light is possible.

If it's cubic feet, it's on the (very) heavy side, and you may well get away without much sandwich construction. If you can get 1lb foam and use full sandwich, I think you'd have a better board.

Although it occurs to me, your foam may be the closed cell extruded not expanded open cell variety. If it's the closed cell stuff, I did make a board ages ago, with a sandwich bottom, reinforced footstrap area, and just 2 or three layers of glass over the rest of the deck.

It lasted OK, but the unreinforced deck dented fairly easily. It's so nice not having to worry about dealing with vents and their problems, that the extra weight is probably worth it.

Greatly appreciate your input. The EPS is expanded, its 2lb, density per cubic foot , pcf. It's very different to 1 lb, which I have in bits from Cobra boards. I was able , after a lot of research to obtain the blank local, without shipping, huge plus was they have a BASIC CNC machine.

i intend to Corecell the footstrap area , extending to mast track would be easy with little weight gain, IMO.

A lot of factors weight( pun not intended) into this. It's going to proceed with the 2lb. Any weight gain will be carefully considered.

again thanks

I think the deck will dent very easily, the eps will suck up resin making the board heavier or pull more resin out of the cloth. I think what you will save by not using a full pvc deck, you will loose plus more from the extra weight of the blank.

If your not doing a full pvc deck cause you cant wrap the rails with pvc then replace ths outside perimeter of the blank with 20mm think pvc or balsa ( as a thick pvc block or build up in 5mm balsa layers) shape this as the rail then blend a pvc full deck into this.

I think the deck will dent very easily, the eps will suck up resin making the board heavier or pull more resin out of the cloth. I think what you will save by not using a full pvc deck, you will loose plus more from the extra weight of the blank.

If your not doing a full pvc deck cause you cant wrap the rails with pvc then replace ths outside perimeter of the blank with 20mm think pvc or balsa ( as a thick pvc block or build up in 5mm balsa layers) shape this as the rail then blend a pvc full deck into this.

I tied to post on one of your previous threads, but the computer, forum said it was too old. I read , multi times you board builds.

the PVC, should be the same as Divinycell..? Sound right?

Well U2U2U2, I'd go with what was said on iWindsurf, which seems to be backed up here as well.

By saving, you could end up spending.

Well U2U2U2, I'd go with what was said on iWindsurf, which seems to be backed up here as well.

By saving, you could end up spending.

Noted, at this point I'm leaning towards a partial deck in some laminate. Don't follow..by saving you could end up spending..?

I still consider that some thinking outside the box is needed, I'm not making a Rocket to Mars, but a go- kart to PikesPeak.

Im pretty happy that I've posted here. if you frequent iwindsurf you will get my drift without further. Steve is a friend , his input has been invaluable in my projects, one of a few that have actually seen one, the very first one.

If you use at least 7 layer's of carbon for the feet area and mast track, it will hold up if the bottom of the board has shape like V or double concave.

But of mine made over 120 epoxy custom sailboards, mostly 8'2-8'4" x 21's, and of all of those, maybe only 5 ended up delaminated, by big heavy rider's.

Mine lasted well over 100 days of usage, or 3 seasons, without any apparent deck damage.

The boards were built in the garage of the house I was living in, so I saw the process thru 2.5 year's of time.

Well U2U2U2, I'd go with what was said on iWindsurf, which seems to be backed up here as well.

By saving, you could end up spending.

Noted, at this point I'm leaning towards a partial deck in some laminate. Don't follow..by saving you could end up spending..?

I still consider that some thinking outside the box is needed, I'm not making a Rocket to Mars, but a go- kart to PikesPeak.

I was referring to the possibility of gaining more weight than you had expected, but I like the idea of a "partial" but the top rails of the nose area would still be a fragile area for mast slams.

Here's another one for you, "don't jump over dollars to save nickels". ![]()

Well U2U2U2, I'd go with what was said on iWindsurf, which seems to be backed up here as well.

By saving, you could end up spending.

Noted, at this point I'm leaning towards a partial deck in some laminate. Don't follow..by saving you could end up spending..?

I still consider that some thinking outside the box is needed, I'm not making a Rocket to Mars, but a go- kart to PikesPeak.

I was referring to the possibility of gaining more weight than you had expected, but I like the idea of a "partial" but the top rails of the nose area would still be a fragile area for mast slams.

Here's another one for you, "don't jump over dollars to save nickels". ![]()

the weight gain will have to be carefully monitored. If it turns out strong and performs well, but is heavy, 2 outta 3 aint bad.

I'm not in Cally where i can walk into a store a walk out with blanks and materials.

i don't recognize your username here on IWindsurf... who are you ?

Yeah its really annoying that you can't post on old threads like on most other forums, not the best of ideas.

When I say pvc yes I mean divinycell or corecell.

My intent on posting was to get your thoughts, and not so much defend my original ideal/ concept.

which I still feel has a option.

at this point, I was planing on some core material between the straps, if now going forward mast track area or beyond but not full deck, , IMO, would not increase the weight while not using multi glass layers, does this make sense ?

the nose impact zone is always a concern , Kevlar and S glass for sure.

no construction is beyond my capability, I want to keep it simple and obvious light weight while using the 2lb.

value all input, Cheers

Hi so excuse my ignorance , but are these boards re shaped out of old boards to creat the

blanks? how do create the new width?

hang loose every body. ive got a week off

umm, those 2 were a reference for the work that previously I had done. No worries, however. The right one had the most of rail width narrowed, except the widest part. The basic outline is F2 Barricuda. volume from 104 to 94, Mistral Naish Score. Trailing tri fin setup, more weight gain that I would have liked, sails well, learned a lot used way to much epoxy to try and make it perfect.

The left side large striped kept most of the rail, except of course in the nose and tail, basic outline is from a Robin Mair surfboard, with some variations. The approx volume went from 109 to 96. Naish Titan. Very good result with this, little drag from quads, weight increase was kept to a minimum.

Both of these are lengthy projects, I think a complete board build with be somewhat easier, dont have to remove everything to start with.

But its a great recycle and re use purpose!

I have a Barracuda 82 sitting in the shed . cracked but still 6kg. one of my favourite boards!

>>>>

at this point, I was planing on some core material between the straps, if now going forward mast track area or beyond but not full deck, , IMO, would not increase the weight while not using multi glass layers, does this make sense ?

the nose impact zone is always a concern , Kevlar and S glass for sure.

no construction is beyond my capability, I want to keep it simple and obvious light weight while using the 2lb.

value all input, Cheers

OK, as I said, I've made one board like this, and it was fine except for being soft where there was no d-cell, but I only used a few layers of 6oz glass, (probably 3 but can't remember). And I suspect the foam i used was a bit lighter than yours, (I think Rider has the details on extruded foam densities,) but I think it changed from about 24kg/m3 to the 32kg/m3 that you're using.

Way back when, some of the Hawaiian guys were using a carbon/kevlar/carbon layup with no d-cell, but I can't remember what sort of foam they used. I'm fairly certain this would be stiff and strong enough, but no idea on weight. A single layer of 8oz carbon/kevlar, may do the trick, but it's a real pain if you sand into it. If you do the deck first and wrap the bottom glass over the rails then just sugar coat the deck without sanding you could get away with it.

With my board, after I'd shaped the deck, I sunk something into the deck at the heel area, the depth of the d-cell, then shaped down to that mark, tapering up to the foam outside the impact area, leaving a slightly concave area in only one plane, (it's too hard to bend the d-cell in complex curves). I then wet out carbon pads a bit larger than the concave area and vacuumed the d-cell on, then shaped the d-cell down to the styrene.

I think an 8oz layer of carbon kevlar over the top of this would be adequate.

May be you could do some tests, on smallish pieces of foam. I attached a tow ball to a drill press, placed weight scales under the press, and used that to dent various layups, pulling to the same weight each time, I then measured the dia of the dent. try 2 layers of 4oz on some 80Kg/m3 d-cell then compare that to your alternative layups on your 2lb foam.

I'd be very interested to hear your results.

>>>>

at this point, I was planing on some core material between the straps, if now going forward mast track area or beyond but not full deck, , IMO, would not increase the weight while not using multi glass layers, does this make sense ?

the nose impact zone is always a concern , Kevlar and S glass for sure.

no construction is beyond my capability, I want to keep it simple and obvious light weight while using the 2lb.

value all input, Cheers

OK, as I said, I've made one board like this, and it was fine except for being soft where there was no d-cell, but I only used a few layers of 6oz glass, (probably 3 but can't remember). And I suspect the foam i used was a bit lighter than yours, (I think Rider has the details on extruded foam densities,) but I think it changed from about 24kg/m3 to the 32kg/m3 that you're using.

Way back when, some of the Hawaiian guys were using a carbon/kevlar/carbon layup with no d-cell, but I can't remember what sort of foam they used. I'm fairly certain this would be stiff and strong enough, but no idea on weight. A single layer of 8oz carbon/kevlar, may do the trick, but it's a real pain if you sand into it. If you do the deck first and wrap the bottom glass over the rails then just sugar coat the deck without sanding you could get away with it.

With my board, after I'd shaped the deck, I sunk something into the deck at the heel area, the depth of the d-cell, then shaped down to that mark, tapering up to the foam outside the impact area, leaving a slightly concave area in only one plane, (it's too hard to bend the d-cell in complex curves). I then wet out carbon pads a bit larger than the concave area and vacuumed the d-cell on, then shaped the d-cell down to the styrene.

I think an 8oz layer of carbon kevlar over the top of this would be adequate.

May be you could do some tests, on smallish pieces of foam. I attached a tow ball to a drill press, placed weight scales under the press, and used that to dent various layups, pulling to the same weight each time, I then measured the dia of the dent. try 2 layers of 4oz on some 80Kg/m3 d-cell then compare that to your alternative layups on your 2lb foam.

I'd be very interested to hear your results.

i do think the density is going Confused not interpreted correct ....or not.. the deck of my Tabou is dented a lot..doesn't effect anything, mast track forward..

i like the concept of testing, and were my professor friend here, it would be interesting. I have devised a test of fin box, was surprised how much it took to dislodge, swinging a weight at a mock fin, installed in the nose of a board.

im close to sorting out the deck, but could change once underway.

do you use pour foam , 2 stage, ..? I'm thinking use 8 pound in the fin box areas, foot inserts, mast track, at the initial stage, so all core cell carbon , glass on top, I would router out, and insert box using carbon glass ? Rationale, no epoxy using PVC , lighter..?

>>>>>>>

i do think the density is going Confused not interpreted correct ....or not..

OK I've done it the long way, and looks very similar.

1 cubic foot = .0283168 cubic meters.

1lb = 0.453592

so 1lb/cubic foot = 0.453592/0.0283168

= 16.018

So 2 lb per cubic foot is about 32Kg per cubic meter.

On my wave boards I've use 20kg/m3 and on my speed boards 13Kg/m3, and I have a surfboard made from 16Kg/m3 foam

the deck of my Tabou is dented a lot..doesn't effect anything, mast track forward..

Yep , the board I made lasted for ages, didn't look that good with a dented deck, but it didn't affect it's performance.

i like the concept of testing, and were my professor friend here, it would be interesting. I have devised a test of fin box, was surprised how much it took to dislodge, swinging a weight at a mock fin, installed in the nose of a board.

im close to sorting out the deck, but could change once underway.

do you use pour foam , 2 stage, ..? I'm thinking use 8 pound in the fin box areas, foot inserts, mast track, at the initial stage, so all core cell carbon , glass on top, I would router out, and insert box using carbon glass ? Rationale, no epoxy using PVC , lighter..?

Not sure what you mean by 2 stage pour foam, we have a 2 part foam mix, that we use for filling voids, dings etc but it isn't very dense.

I don't think you need to use foam that heavy, unless you're using shallow finboxes, sorry I keep thinking of my speed boards where the fin box goes all the way thru to the deck, it doesn't get any support from the core foam, it just needs to be water proofed. But I think 8lb foam is probably over kill, we typically use 80kg/m3 which is 5lb.

Also don't understand "no epoxy". I used 2 layers of 4oz cloth straight into 13kg foam on my last few boards to save weight, lasted for 3 to 5 years then the front footstrap plugs started pulling out. I've now sunk some 24kg/m3 extruded foam around them. My wave boards have all been done this way, inserts straight into 24kg foam (1.5 lb) and they haven't been a problem. But at the surface they're held by a carbon/pvc/carbon sandwich.

This comes in 2 and 8lb versions. Mix 50/50 pour into cavity, it expands , its light, waterproof, dense, very easy to work with.

my thought was instead of using epoxy , and a PVC MATERIAL as support around the fin, foot and mast track boxes, I may use the pour foam in a cavity instead , then place the fittings using my Norman methods. Pour foam , doesn't need epoxy.

i have weighted epoxy , and it adds up quickly. The pour foam itself is heavier, not sure once you account into the epoxy.

Haven't seen that stuff here, the stuff we get would need a lot of compression while it's going off, to achieve any density at all.

Decrepit I think he's talking about 2 part urethane foam it comes in two cans you mix together and its expanded density is about 30kg/ m

Decrepit I think he's talking about 2 part urethane foam it comes in two cans you mix together and its expanded density is about 30kg/ m

Yep, I've got some, but the stuff I've got seems a lot lighter than that, although I haven't measured it. Just my impression from working it. Maybe I'll read the label tomorrow.

I think you know what it is, sounds correct. Most all the marine material suppliers sell it, many different brands. I have used it since day 1 for fin box installation , as a structure from the hull to deck, I router a hole larger than the box, fill with the pour foam, then rerouted out slightly larger than the box, then fit fin box with carbon/. Glass. I've removed these and they prove quite sound.

i feel this will be as strong as Corecell , weight , since no epoxy is involved, until the box gets fitted is less.