One of my fuselage has several knicks down it. I call them knicks but I'm sure that's what they really are. I've only used this fuselage at a sandy beach/launch/location and while I have hit the bottom sand a couple of times, I don't believe I've hit rocks. Further to this, I also have knicks on the upper side of the fuselage (the bottom picture). I store this fuselage the same as others (leaning against a wall or lying on a soft bag). One thought I had is that the aluminum had some contamination prior to anodizing and the salt water corroded the anodizing and aluminum in those areas. While I know a little bit about anodizing, I'm certainly no expert - maybe my explanation is not possible.

Has anyone seen anything like this before?

Anodising can be done in various thicknesses, the thicker the more corrosion resistant and suitable for marine use.

Your suspect fuselage probably has a thinner anodising coating than the others, just a different batch. Luck of the draw really, and you pulled a lemon.

Nothing can be done, it will continue to corrode, going inter granular down the grain lines. Alloy fuselages are strong but should be considered consumable, eg replaced as required.

Contact mfg, maybe they will replace it. For salt water all carbon is best IMO. Could treat with Boeshield T-9 will prevent further corrosion at those spots, based on my experience with aluminum extensions. But may have to reapply regularly as protective wax layer wears off.

I have the same problem with my phantasm fuse

It's not that old and goes realy crusty

I dry it every time now and spray it with wd40

Seems to stop it getting worse

I have the same problem with my phantasm fuse

It's not that old and goes realy crusty

I dry it every time now and spray it with wd40

Seems to stop it getting worse

Slingshot are supplying replacement fuselages under warranty due to this problem.

My attitude has been to think of it as being something that I will have to replace at some point, kind of like all gear. I've also thought about removing the anodizing and getting it re-anodized. Anodizing is cheap if you can get join up with someone else's batch.

Contact mfg, maybe they will replace it. For salt water all carbon is best IMO. Could treat with Boeshield T-9 will prevent further corrosion at those spots, based on my experience with aluminum extensions. But may have to reapply regularly as protective wax layer wears off.

I'll look into Boeshield T-9, I've never heard of that. I put some tef-gel on it but I don't know if it does anything.

Contact mfg, maybe they will replace it. For salt water all carbon is best IMO. Could treat with Boeshield T-9 will prevent further corrosion at those spots, based on my experience with aluminum extensions. But may have to reapply regularly as protective wax layer wears off.

I'll look into Boeshield T-9, I've never heard of that. I put some tef-gel on it but I don't know if it does anything.

Inox mx5 works for me , and useful for lots of other things too , bikes etc.

Contact mfg, maybe they will replace it. For salt water all carbon is best IMO. Could treat with Boeshield T-9 will prevent further corrosion at those spots, based on my experience with aluminum extensions. But may have to reapply regularly as protective wax layer wears off.

I'll look into Boeshield T-9, I've never heard of that. I put some tef-gel on it but I don't know if it does anything.

Boeing made Boeshield T-9 for airplane aluminum corrosion, has anticorrosion chemicals and leaves a hard layer of wax on top.

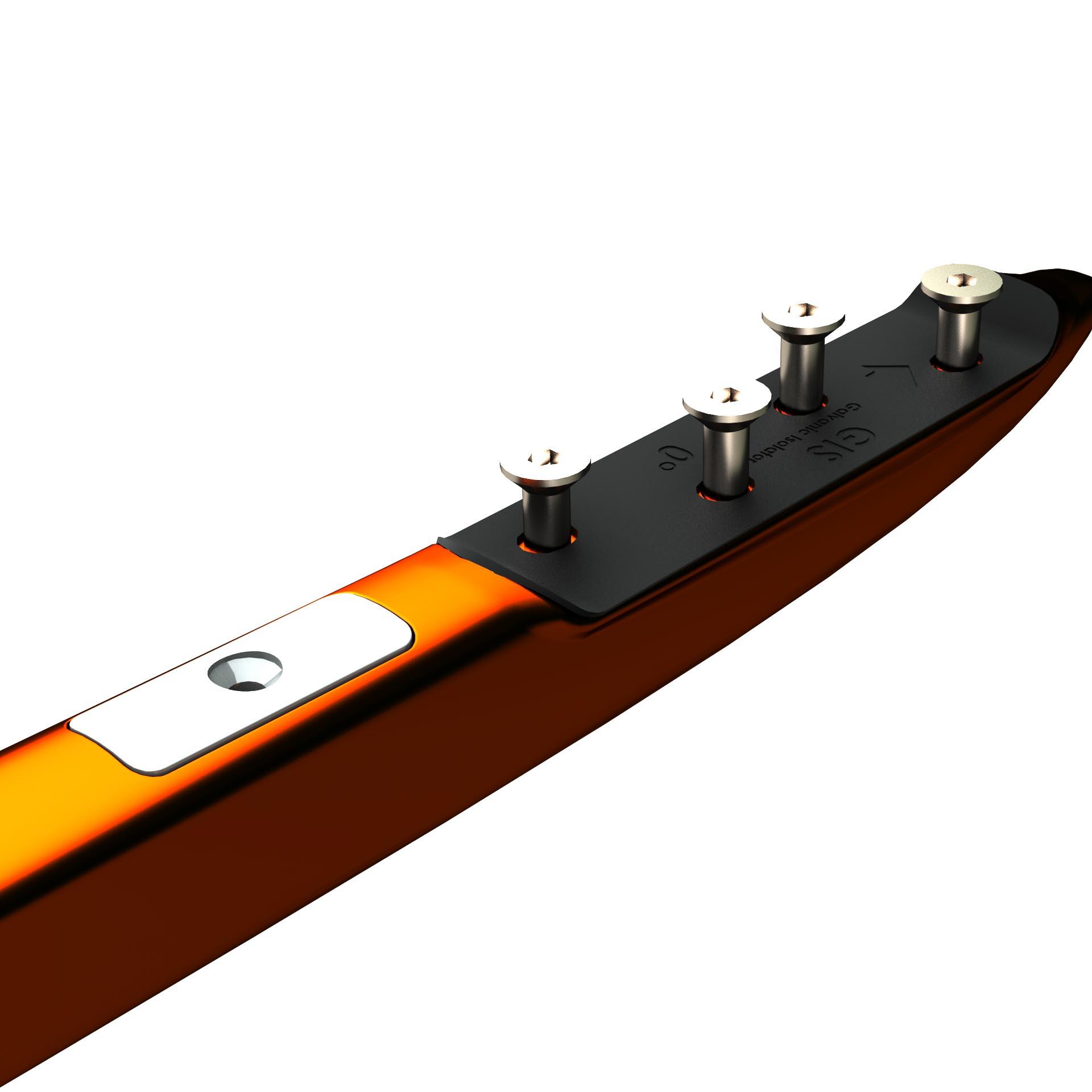

Does anybody have pics of a zinc anode and how it is attached? Good idea for hypersaline water in Florida.

Does anybody have pics of a zinc anode and how it is attached? Good idea for hypersaline water in Florida.

www.seabreeze.com.au/forums/Windsurfing/Foiling/Making-A-Fuselage?page=1#15

Hope Mr. Love can describe the anode itself. I keep seeing big blocks of zinc for boats, etc online.

Alpine Foil's version

I tried this about 6 months ago - had maybe 20 sessions on it before Jesper got me a replacement fuse.

I didn't notice as much pitting in the zinc anode as I expected and I think that patch next to the anode got worse.

Contact mfg, maybe they will replace it. For salt water all carbon is best IMO. Could treat with Boeshield T-9 will prevent further corrosion at those spots, based on my experience with aluminum extensions. But may have to reapply regularly as protective wax layer wears off.

I'll look into Boeshield T-9, I've never heard of that. I put some tef-gel on it but I don't know if it does anything.

Boeing made Boeshield T-9 for airplane aluminum corrosion, has anticorrosion chemicals and leaves a hard layer of wax on top.

Are the different variations of Boeshield T-9 just a difference in packaging? The smaller bottles vs spray can would make the most sense to me I think.

Contact mfg, maybe they will replace it. For salt water all carbon is best IMO. Could treat with Boeshield T-9 will prevent further corrosion at those spots, based on my experience with aluminum extensions. But may have to reapply regularly as protective wax layer wears off.

I'll look into Boeshield T-9, I've never heard of that. I put some tef-gel on it but I don't know if it does anything.

Boeing made Boeshield T-9 for airplane aluminum corrosion, has anticorrosion chemicals and leaves a hard layer of wax on top.

Are the different variations of Boeshield T-9 just a difference in packaging? The smaller bottles vs spray can would make the most sense to me I think.

I have only seen T-9 in a spray can, and what I do for small areas of corrosion is to pulse spray it into a small clear plastic condiment container using the red straw at the bottom edge and nearly all the spray from the pulse collects on the wall and drains down, then I soak a Q-tip in the fluid and apply to corrosion areas. That uses very little T-9 and does not waste it with overspray, and you can reuse Q-tip many times.

Just saw the dropper bottle T-9 online, should be the same as spray can.

Read that it can be used below waterline, so perfect for your foil mast.