Stronger, better, faster, lighter - materials in Kitesurfing

Olympics means money, lots of it. And the fact that it’s a new sport where Australians have a good chance of winning gold means even more cash when it comes to equipment and training. So where is it all going to go? Not the current gear, that’s for sure.

First, lets have a look at the current model kites on offer, which fall into two real categories. There’s the all rounder, things like the North Rebel and Cabrinha Switchblade that have a strong bias on durability and ease of use.

Then there’s the high performance gear, which at the moment isn’t all that different from the freeride gear. But it’s a little harder to use and there’s slightly less emphasis on how long they’ll last. While performance is marketed as a selling point, kite companies still build them tough, and with conventional materials.

This, for an elite level athlete, is simply not good enough. An athlete wants the best equipment, and he or she isn’t paying for it, so the price isn’t really a consideration. Enter the exotic fabrics, carbon, Kevlar and all the unknown fibers that are top secret right now.

If you want a glimpse into what race kites will look like in 5 years from now, check out some of the high performance racing yachts and dinghies on offer at the moment. Paying $10,000 for a sail isn’t a big deal. Nor is shredding it 6 months later. They are lighter, more efficient and produced in a far more efficient manner than our current model kiteboarding kites.

The first thing we’ll see, and it’s already happening, is laminated fabrics in conventional ripstop material. Airush have just released word that their high-end freestyle and wave kites will have Kevlar laminated within the fabrics, in a web pattern to increase torsional strength and durability. Cabrinha released a kite two years ago called the Crossbow X-something) which was made from a monofilm type material similar to windsurfing sails. The idea behind it wasn’t to increase strength, (in fact it was the opposite) but to stop panels from deforming between the seams. These seams (that are found on all kites at the moment) are not only double the thickness of the rest of the kite, but also have a layer of tape, glue and stitching which makes them far stronger than the single sheet of ripstop (Or Dacron). By eliminating the stretch between the panels, you get an airfoil, which is truer, more efficient and better performing. Expect to see lots more innovation in this regard over the next 1-3 years.

Currently a few years away from the kiteboarding industry, are molded kites. Yep, fully molded, no seams. At least there won’t be on the canopy. Currently the yacht sail makers are doing it, by actually creating a full size mold on the loft floor. Then suspending a guy over it on a harness to lay the material either by using a plastic based monofilm and heating it, or by using computer software to actually weave the fabric itself into the molded shape. No seams mean no hard points, it also could reduce the kites weight by around 20% because there will be no wasted material in the overlapped sections. Yes, one would have to take care when packing the kite up, but when you consider the massive trailers that the sailors cart around, having 3 kites rolled up into a tube in the back of their station wagon doesn’t really seem an issue.

Speaking of weight, that’s where the third saving comes into it. Lighter, thinner bladders could cut out 5-10% of a kite’s weight. Lighter fabric could take off 50%, less reinforcing, lighter control lines etc. The list goes on, and because it’s the easiest to do with current materials, this is what you’ll see first from the kite companies.

It’s all going to benefit you as a consumer too, like all things in the modern world the elite level equipment eventually filters down through the market to general consumers. The cost won’t necessarily be slapped on everyone, as by then the research and the big players in the industry will have already done all the research and development, so it’s kind of a win/win for every average kiteboarder out there.

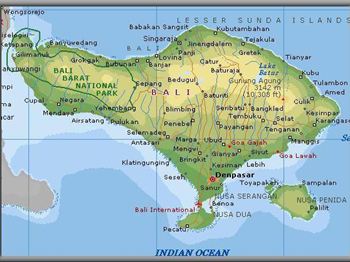

The cost to the big players though, and for the Australian Tax payers (who will ultimately be funding such equipment), will be pretty high when you compare it to what’s currently being spent on gear. From current speculation, a race kite could cost in excess of $5000 by the time the Rio Olympics come around, and the research and development of such a kite could be into the hundreds of thousands of dollars.

It’s pretty exciting times ahead for the sport really, the performance of kites in general is going to skyrocket, new exciting materials will be invented and utilized, and there will finally be a true elite level range of equipment on offer for those willing to spend the cash. That’s just with kites too; wait until the boards catch up!

Check out this video below of how the North yacht sails are laid in a single film.